Development of the static and dynamic mathematical models of the central processing facility of the oil/gas-condensate field

CUSTOMER:Oil company exploring and operating oil and gas fields at the eastern part of the Orenburgskoye oil/gas-condensate field.

The project was initiated by the Customer to improve operating and economical efficiencies of the field development.

SCOPE OF WORK:

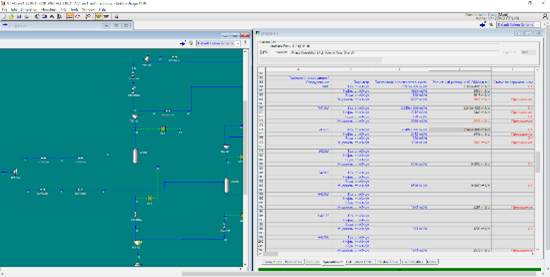

The main objective set to the Nafta Expert specialists was to develop static and dynamic models of the central processing facility of the oil/gas-condensate field by Honeywell UniSim Design software.

The scope of work included the following tasks:

- Development of the static and dynamic models of the central processing facility

- Performing the calculations for the change requests in order to check operational safety in case of changing the operating envelopes

TASKS COMPLETED:

- Development of the static and dynamic models of the central processing facility of the oil/gas-condensate field

- Pipelines bottlenecks checking

- Equipment operating envelopes bottlenecks checking

- Development of the debottlenecking change requests

- Development of the tools in order to automate the defining of the top performance operating envelopes for the various systems

Calculations for the various scenarios provided by the Customer:

- Emergency gas discharge

- Reducing the fuel gas rate by decreasing heaters temperature

- Review of the balance between designed operating envelopes and capacity and actual capacity of the pipelines and installed equipment

- Rescoping of liquid rate in the gas

- Calculation of the maximum capacity of the jump-over lines

- Calculation of the gas system capacity

Training of the Customer staff in terms of the modelling software using and calculation of the forecasting and optimization scenarios

|

|

PROJECT OUTCOMES:

The following calculations were performed based on the developed static and dynamic models:

- Defining the allowable capacity of the static and dynamic equipment and process pipelines

- Analysis of the central production facility operating envelopes changes in case of the various scenarios fulfilment

- Calculation of the central production facility equipment operating envelopes in case of an increase in the oil, gas, water and liquid production levels

- Analysis of the equipment risks in case of emergencies and their potential concequences

Achived results are considered by the Customer as initial information for planning the scope of the reengineering.

The developed models fully fit the Customer expectations and could be used as for the forecasting calculations in order to meet the target production levels as for the focused calculation for the different process systems.