Standardization of the offshore asset maintenance process

Balancing between equipment integrity and reliability on the one hand and maintenance cost and schedule optimization, on the other hand, is one of the most relevant challenges of the Oil and Gas industry under the oil prices cutting. This ambitious target was set under the implementation of the Predictive maintenance information system in one of the biggest oil offshore fields on the Russian shelf of the Caspian Sea. This project was performed by Alma Services Limited Company, a system integrator focused on the development and implementation of databases and information technologies.

Nafta Expert LLC, as a subcontractor, was involved in the project from September 2019 to March 2020 and was in charge of the development of a new and actualization of the current maintenance process guidelines to provide a seamless integration of the Predictive maintenance information system to the field operations management system.

SCOPE OF WORK:

The following works were included to the scope:

- Review of the current field management processes

- Actualization of the local guidelines for the asset organizational units

- Development of the maintenance process KPIs

Analysis and updating of the guidelines were performed by Nafta Expert experienced specialists with practical knowledge of production processes and maintenance methodologies.

|

|

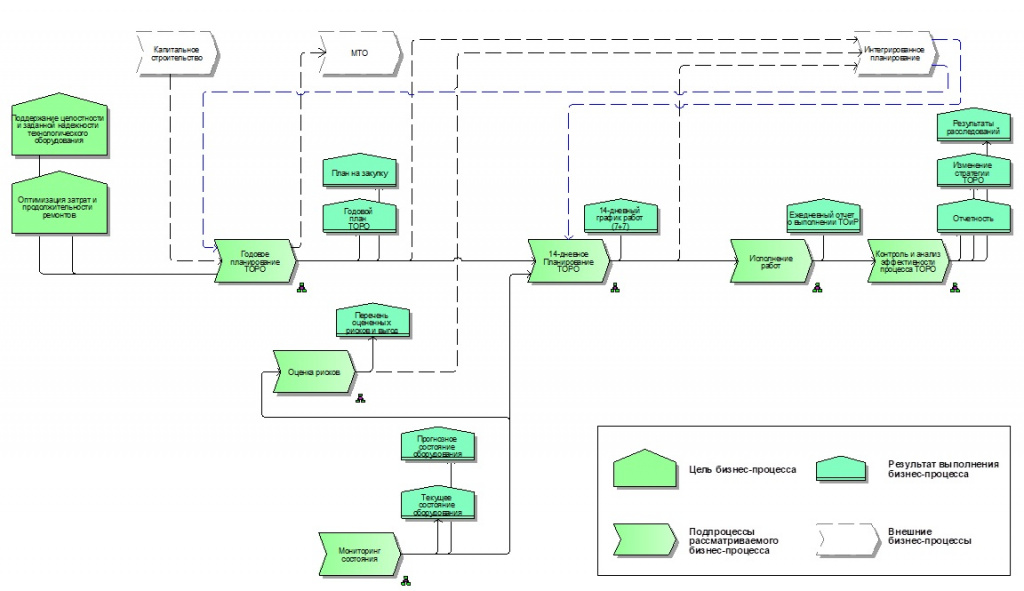

- Business process review, description of the “as is” state, defining of the maintenance process key participants, analysis of the existing processes guidelines

- Development of the high-level maintenance process model with taking into account the Predictive maintenance information system implementation, decomposition of the model sub-processes to the functions level

- Defining the current guidelines to update

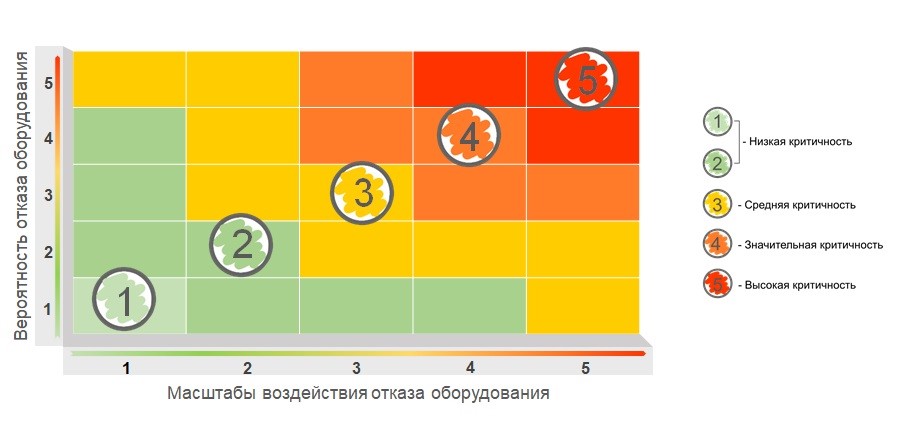

- Development of the Maintenance process guidelines based on both traditional maintenance and risk-based approaches

- Development and updating of the position instructions of the process maintenance process participants

- Analysis of maintenance process KPIs, best practices KPI’s benchmarking, new KPIs algorithms development

PROJECT OUTCOMES:

Application of the development guidelines will allow increasing the quality of the operations in terms of reduction of investments to the field equipment reliability, increasing the time between repairs and level of safety.

The organizational changes allowed defining RACI matrix per each process participants with clear measurable KPIs.

|